Introduction-artificial quartz stone

With the rapid development of modern technology and the continuous improvement of people’s living standards, the requirements for home decoration have also increased. In this process, artificial quartz stone, as a new building material, has gradually attracted people’s attention and love. It has the look and feel of natural quartz stone but with greater strength and durability. In recent years, with the continuous improvement of production technology, artificial quartz stone has also been diversified in color, texture, and size, meeting the needs of different fields. This article will analyze the background, characteristics, applications, and cases of artificial quartz stone to reveal its advantages and application prospects in modern decoration.

1: The History of Engineered Quartz Stone

As the most advantageous facing material, the advantages of quartz stone are evident to all. But how much do you know about the origin of quartz stone? Today, I will introduce to you the history of quartz stone.

Quartz stone was born in Italy in 1984, and the production technology was proprietary to the Italian Bellitone company, so quartz stone was initially called Bellitone stone. Quartz stone is a large-sized plate made of more than 93% quartz crystal, plus 7% resin and trace elements under high pressure under vacuum conditions.

As quartz stone manufacturers’ technology spreads worldwide, quartz stone has become a new fashion trend. As of 2007, 28 quartz stone production lines exist in 14 countries and regions worldwide. The global quartz stone market has grown from tens of thousands of US dollars per year in 1984 to the current market size of US$3 billion annually. This rapid development is becoming even faster due to the activation of China’s quartz stone market.

Initially, quartz stone was only used on cabinet countertops, furniture countertops, and laboratory worktops that had higher surface requirements. With the economy’s development and the market’s maturity, more foreign countries have begun using quartz stone in various fields, such as floors, walls, and furniture. For example, quartz stone is gradually becoming a substitute for natural stone in different large hotels, luxury residences, and landmark buildings. The customers who use quartz stone are also constantly changing. From traditional wholesalers to real estate development companies to construction and decoration companies, more and more people are joining the trend of quartz stone consumption.

It is not an accident that quartz stone has achieved such great success: the advantages and characteristics of quartz stone are apparent to all, and the price of quartz stone is acceptable to most people.

1.1 Quartz stone product development direction

Quartz stone products, as a kind of artificial stone mixed with quartz sand, resin, and other additives, have become popular in today’s home decoration field because of their excellent physical properties and beautiful appearance. However, with the intensification of market competition and the continuous improvement of consumer demand, the development of quartz stone products is also facing new challenges and opportunities. In the future, the development direction of quartz stone products is mainly reflected in the following aspects:

1.1.1 Product performance and functions continue to improve

As a synthetic stone, quartz stone products have advantages in physical properties, chemical properties, and environmental performance. However, as consumers’ product quality and performance requirements continue to increase, quartz stone products must continuously improve their basic version. For example, through continuous research and development, we can improve the basic properties of quartz stone products, such as wear resistance, high-temperature resistance, waterproofness, and antifouling, to meet the higher needs of consumers.

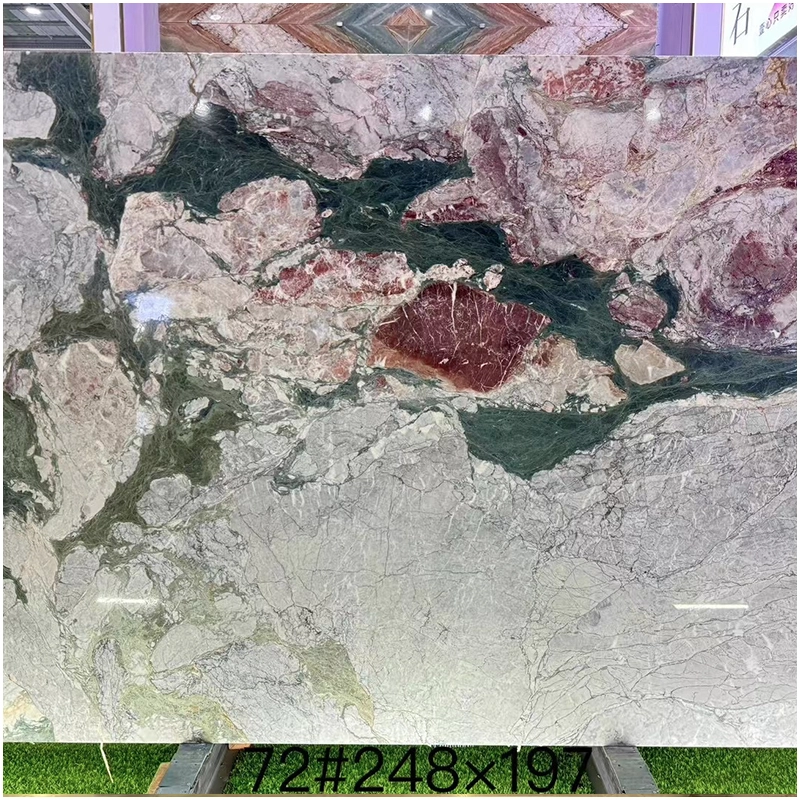

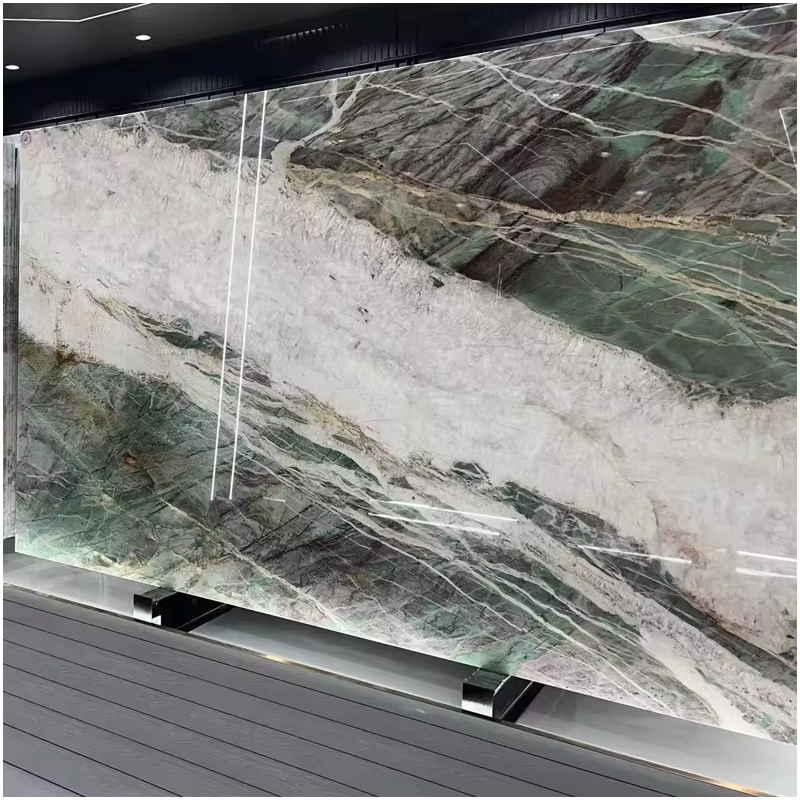

1.1.2 Product appearance is highly simulated

Natural stone still has advantages in decorative and artistic appearance and occupies a high market share in high-end interior decoration. Therefore, it has become the leading industry development direction to produce highly simulated artificial quartz stone products by improving the cloth process, using new molds, and introducing robotic arms for automatic cloth. This positively affected quartz stone product can meet consumers’ needs for aesthetics and reduce the cost of mining and using natural stone, making it more environmentally friendly and economical.

1.1.3 Product production realizes automation and intelligence

As labor costs continue to increase and market competition intensifies, the realization of automated and intelligent production has become an important development direction for the quartz stone industry. Automatic output of fabrics through technology research and development is of great significance to reducing labor costs, improving production efficiency, shortening delivery cycles, and reducing finished product inventory. For example, introducing robotic arms for automatic cloth can achieve precise control and improve production efficiency and quality. In addition, intelligent production lines can realize the visualization and controllability of the production process, enhance product quality and efficiency, and reduce production costs.

1.1.4 Product application fields continue to expand

Quartz stone products are mainly used in cabinets, kitchen island countertops, and other fields. However, as consumers’ awareness and acceptance of quartz stone products continue to increase, their application areas also expand. For example, the application of quartz stone products in window sills, bathrooms, walls, and floors is also growing. In the future, as consumer demand for quartz stone products continues to grow and application fields continue to expand, the development prospects of quartz stone products will also be broader.

To sum up, the development direction of quartz stone products is mainly reflected in improving product performance and functions, achieving high simulation of appearance, realizing automated and intelligent production, and broadening application fields. We can remain invincible only by continuously innovating and improving product quality and service levels in the fierce market competition.

2. What is artificial quartz stone?

Artificial quartz stone is a composite material made of quartz sand, resin, pigments, and other raw materials through high temperature and pressure. It has the look and feel of natural quartz stone but with greater strength and durability. In recent years, with the continuous improvement of production technology, artificial quartz stone has also been diversified in color, texture, and size, meeting the needs of different fields.

The origin of artificial quartz stone can be traced back to the 1980s when some European countries began to study the production process of artificial quartz stone. With the continuous advancement of technology, the quality and performance of artificial quartz stone have been greatly improved, and it has gradually occupied a place in the market. In China, the development of artificial quartz stone has also gone through nearly 20 years. From the initial introduction of foreign technology to domestic enterprises’ independent research and development and production, the artificial quartz stone industry has formed a complete industrial chain. China has become one of the major producers of artificial quartz stone in the world, and its products are exported all over the world.

Artificial quartz stone has many advantages, the most prominent of which are its high hardness and wear resistance. Its hardness is second only to diamond; it is not easily scratched by complex objects such as knives and keys and is very convenient to maintain. At the same time, it also has good corrosion resistance and can maintain stability in various environments. In addition, artificial quartz stone is lightweight and easy to transport and install. It also has good processing properties and can be cut, drilled, polished, etc., making it easy to make into various shapes and sizes. The most important thing is that no radioactive substances are produced during the production process of artificial quartz stone, which is harmless to the human body and the environment.

Due to these advantages of artificial quartz stone, it has been widely used in modern decoration and construction fields. In-home decoration, artificial quartz stone can be used to make kitchen countertops, bathroom sinks, etc. In construction projects, artificial quartz stone can make floors, walls, etc. In addition, it can also be used to make sculptures, fountains, and other artworks, as well as laboratory operating tables, instrument panels, etc. With the continuous development of science and technology, artificial quartz stones’ production process and product performance will be further improved to meet the needs of more fields.

3. Composition and function of artificial quartz stone

Artificial quartz is a synthetic stone made of unsaturated polyester resin as the binder, quartz sand, glass particles as the primary aggregate, and quartz powder as the main filler. It is widely used in interior decoration, especially on countertops such as kitchens, bathrooms, windowsills, and restaurants. Artificial quartz stone inherits the advantages of natural granite’s complex texture, corrosion resistance, wear resistance, exquisite colors, and high grade of natural marble.

3.1. Main components and functions of artificial quartz stone

- Quartz sand (powder): Quartz sand (powder) is the primary raw material of artificial quartz stone. It accounts for a relatively high proportion and plays a role in improving strength and wear resistance. The particle size and distribution of quartz sand significantly impact the physical properties of artificial quartz stone. The finer the particles and the more evenly distributed, the higher the strength and wear resistance of artificial quartz stone.

- Resin: Resin is the adhesive of artificial quartz stone. It tightly binds quartz sand (powder) and other raw materials to stabilize its structure and performance. The resin’s type and content significantly impact the performance of artificial quartz stone. Unsaturated polyester resin is currently commonly used synthetic quartz stone resin. It has good adhesive properties and curing speed and can meet the production requirements of artificial quartz stone.

- Pigments: Pigments give artificial quartz stone various colors and textures to meet the needs of different fields. The type and content of pigments significantly influence the color and texture of artificial quartz stone. The matching and mixing of other stains can create a variety of unique colors and texture effects, giving artificial quartz stone better decorative properties.

- Curing additive: Curing additive is an additive in the production process of artificial quartz stone. It can accelerate the curing reaction of the resin and improve the hardness and durability of artificial quartz stone. The type and content of curing additives greatly influence the curing speed and hardness of artificial quartz stone. Choosing the right curing aid can help artificial quartz stone achieve higher hardness and durability in a shorter time.

- Coupling agent: It improves the interface properties between artificial quartz stone and inorganic fillers or reinforcing materials to enhance its durability and stability. The coupling agent’s type and content significantly impact the durability and strength of artificial quartz stone. Selecting the appropriate coupling agent can ensure that artificial quartz stone maintains stable performance and appearance during long-term use.

In addition to the above main ingredients, artificial quartz stone may also add some embellishment materials, such as shells, transparent glass, colored glass, brass, fluorite, pyrite, sphalerite, etc., to enhance the decorative nature of the product. These embellishment materials can be selected according to different needs and design styles, making the artificial quartz stone more personalized.

3.2 Function of ingredients

- Quartz sand (powder) improves the strength and wear resistance of artificial quartz stone and is the primary raw material of artificial quartz stone. The particle size and distribution of quartz sand significantly impact the physical properties of artificial quartz stone. The finer the particles and the more evenly distributed, the higher the strength and wear resistance of artificial quartz stone.

- Resin: As a binder, it tightly binds quartz sand (powder) and other raw materials, giving the artificial quartz stone a stable structure and performance. The resin’s type and content significantly impact the performance of artificial quartz stone. Unsaturated polyester resin is currently commonly used synthetic quartz stone resin. It has good adhesive properties and curing speed and can meet the production requirements of artificial quartz stone.

- Pigments: Give artificial quartz stone various colors and textures to meet the needs of different fields, such as imitating the texture and color of natural stone. The type and content of pigments significantly influence the color and texture of artificial quartz stone. The matching and mixing of different dyes can create a variety of unique colors and texture effects, giving artificial quartz stone better decorative properties.

- Curing additive accelerates the curing reaction of the resin, improves the hardness and durability of artificial quartz stone, and makes it less likely to be damaged during use. The type and content of curing additives significantly impact the curing speed and hardness of artificial quartz stone. Choosing the right curing aid can help artificial quartz stone achieve higher hardness and durability in a shorter period.

- Coupling agent: Improve the interface performance between artificial quartz stone and inorganic fillers or reinforcing materials, improve its durability and stability, and extend its service life. The coupling agent’s type and content significantly impact the durability and strength of artificial quartz stone. Selecting the appropriate coupling agent can ensure that artificial quartz stone maintains stable performance and appearance during long-term use.

3.3. The influence of the production process on ingredients

In addition to the type and content of ingredients, the production process will also affect the performance and appearance of artificial quartz stone. Reasonable production technology can ensure the quality stability of artificial quartz stone and reduce production costs. Different production processes will affect the density, hardness, wear resistance, weather resistance, and other aspects of artificial quartz stone. Therefore, choosing a professional manufacturer and appropriate production technology and equipment is crucial.

Artificial quartz stone has many advantages and a wide range of applications as a new building material. Its high hardness, corrosion resistance, lightweight, easy processing, environmental protection, and non-toxicity make it an ideal choice for modern decoration and construction. With the continuous development of science and technology, artificial quartz stones’ production process and product performance will be further improved to meet the needs of more fields. Therefore, choosing artificial quartz stone is wise for home decoration or construction projects.

Quartz stone plate quality requirements for quartz sand

As a filler for artificial quartz stone, first of all, its water content should not be too high; otherwise, it will affect the resin’s curing, and the product’s surface will be sticky after curing. The kraft paper on the back will be moist, and there will be water vapor on the surface of the mold. If the board product is cured, If it is not good, it is one of the reasons for cracking during post-processing; secondly, coarse and fine particles should be combined. Generally, the smaller the mesh size of the filler (that is, the larger the particles), the smaller the specific surface area of the particles and the less the resin content. On the contrary, the greater the resin dosage, the more the particular usage can be determined according to the customer’s different plate models and specifications.

In addition, the transparency, whiteness, and grade of quartz sand significantly impact the quality of quartz stone slabs.

3.4 The Influence of quartz sand permeability on quartz stone Slabs

According to quartz sand’s different transparency and whiteness, quartz sand can be divided into permeable, semi-permeable, and porcelain white sand. Porous sand is divided into high-purity and ordinary permeable sand according to the condition of variegated particles. Permeable sand that is entirely pure and transparent (utterly free of non-transparent particles) and has no impurities is called high-purity porous sand, which is very rare and expensive; permeable sand that contains variegated particles is yellow, and some particles are not entirely transparent is called high-purity porous sand. It is ordinary permeable sand, and the price is average. The transparency of semi-permeable sand is between transparent and impermeable; the cost is medium. Porcelain white sand is completely pure white without any fine particles, which is rare and more expensive. The whole body of the transparent sand is crystal clear, refined, and free of impurities, just like glass; the semi-transparent sand particles are partly light-transmitting and partly opalescent; the whole body of the porcelain white sand is entirely opaque and wholly blocked from light, and the edges of the ivory white and vein white particles have a certain degree of opacity. Light can enter, but light cannot pass through completely.

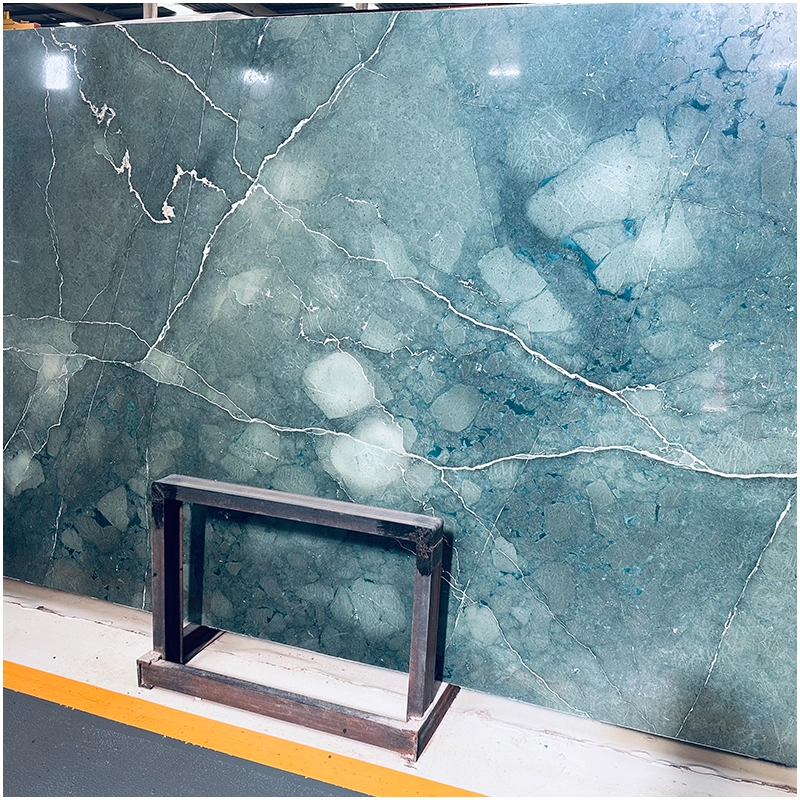

Quartz stone products with black and gray background colors need to use porous sand so that light can completely penetrate, allowing the black and gray background colors to appear; if there are non-transparent particles, they will block the black and gray background colors and appear white—or other colors.

High-end imitation natural stone quartz stone products must use permeable sand to reflect the texture. The more absorbent the board surface, the closer to the texture effect of natural stone: the pattern is faintly revealed from the body and gradually disappears, showing a high-end texture and layering rather than a low-end texture effect floating on the surface. The internationally famous “Calacatta White Marble” can offer a high-end texture with permeable sand.

3.5 The influence of quartz sand whiteness on quartz stone slabs

The whiteness of quartz sand obtained from different mining sources and processing processes varies greatly; some are high in whiteness, and some are yellowish. Whiteness affects the grade of quartz stone slabs. The higher the whiteness, the higher the stage; the yellower the slab, the lower the rate. Fluctuations in different batches of quartz sand raw materials will also significantly impact the appearance quality of the board.

3.5.1 The influence of quartz sand grade on quartz stone slabs

The number of dust particles in quartz sand and the color of the sand itself determine the grade of quartz sand. Many dust particles and yellow coloring will affect the quality and degree of the quartz stone slabs. Therefore, we divide different stages of quartz sand into refined sand, A sand, ordinary sand, C sand, etc.

Refined sand is refined quartz sand. The requirements for advanced sand are incredibly high. It should be completely pure, free of im but purities, and very white. Most of the fine sand is pickled, and a small amount of virgin raw ore can be directly crushed into fine sand. A sand has slightly more impurities than fine sand but has fewer impurities, is white, and has higher requirements.

As the grade of quartz sand decreases, the impurities gradually increase, and the color of the sand also gradually deteriorates. The commonly used refined sand, A sand, ordinary sand, selected quartz, B sand, C sand, etc., on the market, are all composed of mostly transparent quartz plus a small amount of semi-permeable and impermeable quartz. In addition, very high-quality quartz raw ore reserves are small, so the grade of quartz sand must be improved.

4. Quartz stone production process

Quartz is a mineral resource with very stable physical and chemical properties. Quartz stone is an abbreviation for the plates produced by current quartz stone plate manufacturers. Because the main component of the scale is a quartz content of more than 94%, it is called quartz stone.

- 4.1 Quartz stone production process:

(1) Selection of production raw materials

The quality of raw materials directly affects the quality of quartz stone, so it is essential to check the quality from the source and select raw materials.

- Selection of quartz powder:

1) Fineness requirement: 325 mesh or 400 mesh;

2) Whiteness requirement: 95 or above;

3) SiO2 content: above 98%

- (2) Color paste coloring

The color paste’s mixing time and the resin and colorant ratio will directly affect the board’s color.

- (3) Mixing and stirring

In the production process of artificial quartz stone slabs, a single raw material is premixed according to the production order or batch before use to reduce color difference; when mixing, a planetary high-speed mixer is used to ensure the raw materials are thoroughly mixed.

(4) Fabric

Distribution is carried out in the distributing device to meet production requirements.

- (5) Press pressing

Artificial quartz stone sheets are formed under high pressure and strong vibration force in a vacuum state. The synthetic quartz stone sheets produced have high density and low water absorption. The pressurization time varies depending on the formula and plate thickness but is generally 2 to 4 minutes. After the artificial quartz stone plate is pressed, the paper must be peeled off to ensure that the bonding degree between each part and the paper/film is consistent and no localized parts can occur. The entire board must have the same softness when touching the bulge with your fingers.

- (6) Curing

The pressed quartz stone slab is then sent to the furnace for heat curing. The setting of the curing line of the curing furnace is critical because the temperature of the curing line is directly related to the deformation of the solidified quartz stone slab. If the temperature of the curing line is too low, it will cause the plate to deform later. Large: if the temperature above and below the curing line is uneven, it will cause stress on the surface and local parts of the plate. During the polishing process in the later stage, the container will be deformed due to stress release. After the quartz stone slab comes out of the curing line, gently tap various parts of the slab with an iron pipe with a wall thickness of less than 3 mm. The curing effect is good if the sound is crisp; if the sound is dull, the curing result could be better.

- (7) Placement of semi-finished products after curing

For the placement of semi-finished boards, if the shrinkage of the resin is minor, the board can be placed vertically on the A-frame, bottom to bottom; if the shrinkage of the resin is significant, it is recommended to lay the board bottom to bottom, and the surface of the board must be cleaned very clean, to ensure the flatness of the plate in the later stage. The cured plate must be left for 24 hours, and the polishing process can only be carried out after the container has thoroughly cooled.

- (8) Polishing

The smaller the particle size of the plate, the lower the gloss. The gloss after polishing is generally around 40°. The larger the particle size, especially the plate containing large particle glass, the higher the luster. The front after polishing is generally around 60°. Selection of polishing surface: Generally, the surface in contact with the template is selected as the polishing surface because this side has better flatness and smoothness. This side has fewer impurities during the cloth process and has high density during the curing process. Therefore, it is ideal to choose this side as the polishing surface. Selection of grinding blocks: Choose good quality granite stone grinding blocks and a reasonable mesh number. Polishing speed varies depending on the raw material formula and plate color. For example, the linear speed should be slowed during polishing for small particles and solid-color plates. In contrast, the linear velocity can be relatively faster for dishes with large particles of glass particles and light-colored leaves.

4.2 Common problems and solutions in the production process of artificial quartz stone slabs

Due to improper operation and control, various defects will occur during quartz stone production, such as deformation, cracking, fading, discoloration, powder, watermarks, pinholes, pores, impurities, etc. How to avoid the occurrence of these defects and reduce cost waste, the following experience is summarized:

Deformation: mainly related to the formula composition, curing method, whether the curing is sufficient, and whether the storage method of semi-finished products/finished products is appropriate.

The solution is as follows:

1) Develop a reasonable formula structure to adopt affordable and accurate curing methods, such as secondary curing technology, so that the plate can be heated up and down during movement and thoroughly heated.

2) 2) Choose a reasonable storage method based on the quality of the resin.

Discoloration: Discoloration is mainly related to the properties of the resin, colorants, and curing agents.

The solutions are as follows:

1) Use resin with good stability.

2) Use a thermal curing agent to ensure that the curing agent can fully react without leaving any residue during the heating process.

3) Using inorganic colorants, it has good weather resistance.

Pores: There are two major categories of pores. One is small pinholes, usually caused by the vacuum degree not reaching -0.1MPa and the resin content in the formula being too high; the second is large irregular pores, usually caused by the formula structure. Unreasonable, uneven fabric, not dense when pressed by the press, and variable force on the material. The methods to prevent it are: first, use good vacuum equipment, use special vacuum pump oil, and do good maintenance; second, the sealing of the press and pipelines should be good, and the vacuum chamber of the media should be small; third, it should be appropriately formulated. The fourth is good molding equipment and mature production technology and operating procedures.

Watermark: The watermark’s appearance is caused by uneven local pressure and movement of the board during the pressing process, resulting in uneven distribution of the toner used inside the panel. However, presses with solid pressure and vibration, under the control of mature production processes, can prevent this problem very well.

Wear marks are the most common problem, especially on dark and solid-colored boards. Using special grinding blocks can reduce or eliminate such dark marks, and choose a reasonable polishing speed according to the color and particles of the plate.

5:Advantages of artificial quartz stone

Artificial quartz stone is a synthetic stone made of unsaturated polyester resin as the binder, quartz sand and glass particles as the main aggregate, and quartz powder as the main filler. It is widely used in interior decoration, especially on countertops such as kitchens, bathrooms, windowsills, and restaurants. Artificial quartz stone inherits the advantages of natural granite’s hard texture, corrosion resistance, and wear resistance, as well as the exquisite colors and high grade of natural marble.

2. Advantages of artificial quartz stone

High strength and wear resistance: The main raw materials of artificial quartz stone are quartz sand and glass particles, which have high hardness and wear resistance. After high-pressure pressing and solidification treatment, the strength and wear resistance of artificial quartz stone have been further improved. As a result, it remains flat and less susceptible to damage over extended periods of use.

Corrosion resistance: Artificial quartz stone has good corrosion resistance and can resist the erosion of most chemicals. This makes it widely used in laboratories, hospitals and other places where resistance to chemical corrosion is required.

Fire resistance: Artificial quartz stone does not burn and has good fire resistance. It does not deform or produce harmful gases at high temperatures, so it is widely used in public places, schools, hospitals and other places where fire protection is required.

Environmentally friendly and non-toxic: The raw materials and production process of artificial quartz stone do not contain harmful substances, and it is an environmentally friendly and non-toxic building material. It will not release harmful gases and will not cause harm to human health.

Easy to clean and maintain: The surface of artificial quartz stone is flat and smooth, and it is not easy to accumulate dust and dirt, making it very convenient to clean and maintain. Just wipe with a damp cloth to keep it clean and hygienic.

Various colors: Artificial quartz stone can be made into various colors and textures by adding different colors of pigments, which can meet the needs of different occasions and styles. This makes it have broad application prospects in the field of interior decoration.

Economical and affordable: Compared with natural stone, artificial quartz stone is more affordable. Moreover, its production cycle is short, which can meet the needs of rapid decoration and reduce decoration costs and time costs.

3. Conclusion

To sum up, artificial quartz stone has many advantages such as high strength and wear resistance, corrosion resistance, fire resistance, environmental protection and non-toxicity, easy cleaning and maintenance, various colors and economical benefits. Therefore, it has been widely used in the field of interior decoration. With the continuous development of science and technology, the production process and product performance of artificial quartz stone will be further improved in the future to meet the needs of more fields.

Disadvantages of artificial quartz stone

higher price

The price of artificial quartz stone is generally higher than that of natural stone and other artificial stones, making it one of the more expensive kitchen countertop materials. The main reasons for its high price include the following aspects:

High raw material costs: Quartz sand is the main raw material for artificial quartz stone, and its price is relatively high.

Complex production process: The production process of artificial quartz stone is relatively complex and requires higher technology and equipment.

Strong brand influence: Brand competition in the artificial quartz stone industry is fierce, and the prices of well-known brands are generally higher.

Single shape

Artificial quartz stone has a high hardness, so it is difficult to splice, has a single shape, and is not easy to make complex shapes. The main reasons for its single shape are as follows:

The hardness of quartz sand is high: the hardness of quartz sand is about 7, which is higher than the hardness of natural stone, so higher technology and equipment are required in the splicing process.

Lower strength of resin: The lower strength of resin requires a thicker layer of resin during the splicing process, which results in an increase in the thickness of the countertop.

Cost factors: The production cost of complex shapes is high, so they are rarely used in practical applications.

Risk of cracking

Although artificial quartz stone has a certain degree of heat resistance, when it expands due to heat, if the internal stress is too large, it may cause cracking. The main reasons for its cracking risk include the following aspects:

Excessive internal stress: Artificial quartz stone will generate a certain amount of internal stress during the production process, which may lead to cracking if not adequately processed.

Improper installation: Failure to pay attention during the installation process of artificial quartz stone may lead to increased internal stress, thereby increasing the risk of cracking.

Improper use: If artificial quartz stone is hit hard during use, it may cause cracking.

Repair difficulty

Once artificial quartz stone cracks, it is difficult to repair and requires professionals to repair it. The main reasons for its difficulty in repair include the following aspects:

High degree of cracking: Artificial quartz stone has a high degree of cracking, which may cause the overall deformation of the countertop, which will increase the difficulty of repair.

Complex internal structure: The internal structure of artificial quartz stone is complex, which will increase the difficulty of repair.

Requires professional equipment: Repairing artificial quartz stone requires professional equipment and technology, which will increase the cost of repair.

Other disadvantages

In addition, the surface of artificial quartz stone is generally polished, so a large amount of dust will be generated during the processing, which will cause certain pollution to the environment.

Overall, artificial quartz stone has certain advantages, but there are also some disadvantages. When choosing artificial quartz stone, you need to comprehensively consider its advantages and disadvantages and make a choice based on actual needs.

Related Products

Calacatta Artificial Quartz Countertops

Calacatta Quartz Countertops

Artificial Quartz Kitchen Countertop