FORU Brand Introduction

FORU Stone was established in recent years. With its excellent stone processing technology and high-quality products,, it has first-rate stone processing technologies and premium goods. FORU is dedicated to provide consumers premium stone solutions and concentrates on mining and processing natural stones. FORU has developed a good name in the market by means of great workmanship, vast industrial expertise, and rigorous quality requirements.

Many different stones, including marble, granite, quartzite, etc., are covered by FORU’s goods; they are extensively employed in many different industries including building, decorating, and landscaping. Emphasizing product research and development and innovation to satisfy various consumer requirements, the brand has consistently followed the guiding idea of “quality first, customer first”.

FORU Stone’s features and benefits

Superior raw materials

FORU’s chosen stone blocks are all from premium mining sites, therefore guaranteeing the naturalness and durability of the stone. By means of many stone mines, FORU is able to provide a wide range of stones and maintain a constant supply capacity.

Modern technology in processing

To enable the cutting, grinding, and carving of stones to achieve a polished degree, FORU has brought cutting-edge equipment and technology into the stone processing process including digital cutting machines, CNC machining centers, etc., These technologies guarantee the accuracy and beauty of the produced stone items in addition to raising manufacturing efficiency.

strong range of products

Large slabs, stone crafts, parquet flooring, wall decorations, etc., among other stone goods FORU offers, may satisfy a range of demands in many sectors and consumer base. FORU also offers tailored designs and customized services based on consumer requirement.

Expert after-sales assistance

FORU gives the customer’s experience high value and offers thorough after-sales care to guarantee that the issues consumers run into using the items may be promptly addressed. The business has a skilled customer care staff to provide clients help and advice whenever they so want.

Leanoms DTH drill bit aids FORU stone

FORU is under further production pressure as stone market demand keeps rising. While guaranteeing stone quality becomes a challenge FORU desperately needs to address, how can production efficiency be raised? This is the setting in which LEANOMS’s DTH drill bit offers a workable option for FORU stone.

Mine capacity for efficiency

Strong rock breaking capacity and fast and efficient penetration of many hard rocks define LEANOMS’s DTH drill bit. DTH drill bits may greatly cut the mining time and increase work efficiency in the process of stone mining. This implies that more stone blocks may be acquired quicker for FORU STONE to satisfy market need.

Reliable drilling control

Designed properly, the DTH drill bit may get precise drilling control. This precision lowers the waste of stone blocks, therefore enabling FORU STONE to optimize the use of every mined stone and enhance resource economy. Along with lowering manufacturing costs, this enhances the company’s environmental reputation.

Adaptable deep hole drilling technology

Whether in strong granite or more delicate marble, the DTH drill bit’s deep hole drilling technique fits many different geological settings. She can easily handle that. The adaptability of this technology helps FORU STONE to mine effectively in many mining sites, therefore broadening the field of mining.

Lower running expenses

Using LEANOMS’s DTH drill bit helps FORU STONE not only increase mining efficiency but also drastically lower running expenses. The DTH drill bit’s effective performance lowers the time and labor expenses in the mining operation, thereby giving the business more edge in market competitiveness.

Stone block processing technique

FORU STONE employs its sophisticated processing equipment and technologies to carry out additional processing of the high-quality stone blocks once they have been effectively mined. This mostly involves the following links:

Blocks cutting

The mined stone blocks will be sent to the processing factory for cutting after first inspection. To cut the blocks into the necessary size and form, FORU Stone use digital cutting technology and highly precise cutting tools. This procedure guarantees consistent thickness of the big slabs as well as tidy edges and corners, thereby providing a strong basis for further processing.

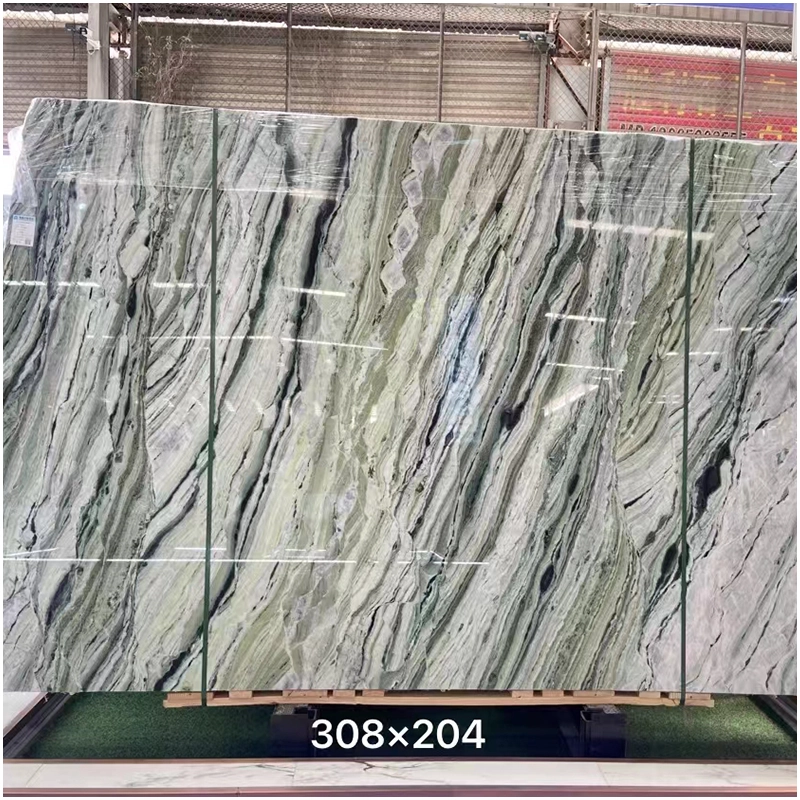

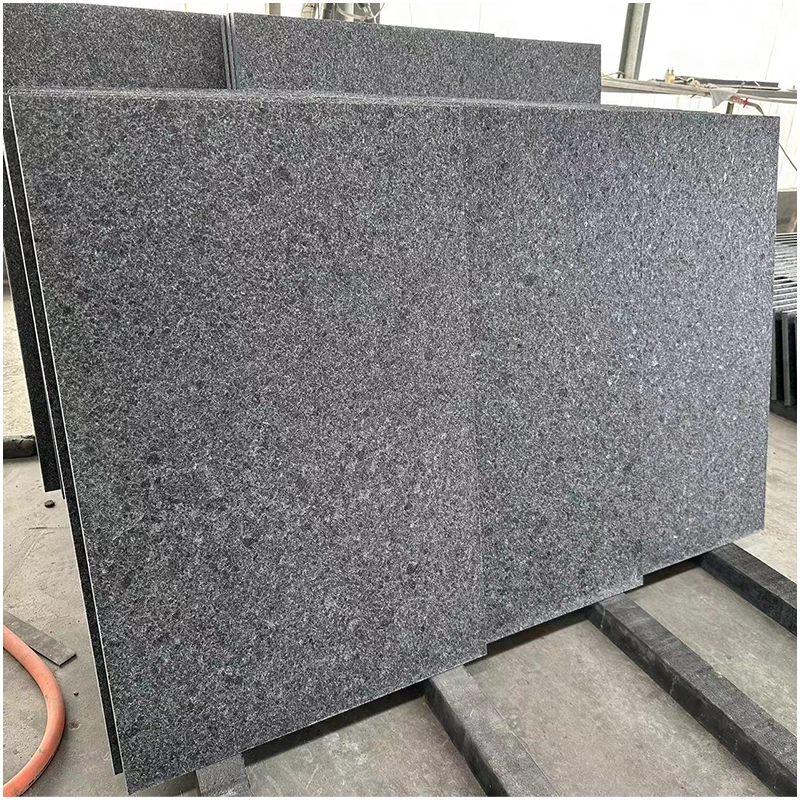

Large slab manufacturing

The stone is chopped into big slabs after that. Widely utilized in building, decorating, and other sectors, FORU Stone has excellent stone processing technologies and can create stone slabs of different standards. These big slabs not only satisfy market need but also show FORU STONE’s rigorous control of product quality.

Handicraft production

FORU STONE uses superb carving and design to turn those stone blocks with poor placement and uneven form into distinctive stone crafts. FORU STONE is able to create beautiful decorations and artworks by means of superior carving technology and workmanship, therefore augmenting the added value of stone and improving the product line of the firm.

fine gritting and quality control

FORU Stone will also do fine grinding after big slabs and crafts are finished to guarantee that the surface of the stone is perfect to satisfy client needs. Simultaneous rigorous quality control guarantees that every completed stone satisfies international criteria, therefore guaranteeing consumer safety and durability during usage.

Perfect cooperation between LEANOMS and FORU Stone

DTH drill bits from LEANOMS enable FORU Stone to mine premium stone blocks in a more accurate and efficient manner, thereby significantly increasing the efficiency of stone mining and so lowering the harm to natural resources during mining. By means of its expert stone processing technology, FORU Stone is able to preserve its leadership position in the stone market and produce high-end huge slabs and beautiful crafts, thereby offering clients more varied options.