Marble Production

Natural marble is mostly the result of limestone metamorphism under high temperature and pressure. Although we cannot directly produce marble in an artificial environment, we can mine, process and manufacture natural marble into useful building and decorative materials.

Marble Mining

Mine Exploration

Finding high-quality deposits is the first step in the marble production process. In order to determine the location, quality and reserves of the deposits, geologists use exploration.

Geological Survey: Locate and explore marble deposits using geological exploration methods (including seismic surveys, drilling and geological mapping).

Sample Analysis Collect rock samples and evaluate the quality and viability of marble through chemical and physical examinations.

Mining

Marble mining begins after the establishment of the deposit.

The marble is separated from the deposit by blasting and cutting using appropriate equipment. Chain saws and diamond wire saws are two commonly used cutting tools.

Stone Separation: Large pieces of stone are removed from the mountain using lifting equipment and transported to the processing plant.

Preliminary Processing of Marble

Processing Roughness

Large pieces of raw stone are first processed to cut them into smaller slabs or blocks.

Cutting: Large blocks of raw stone are cut into regular-sized blocks or slabs using large stone saws.

Rough grinding: To eliminate surface irregularities and flaws, the cut marble slabs are first rough ground.

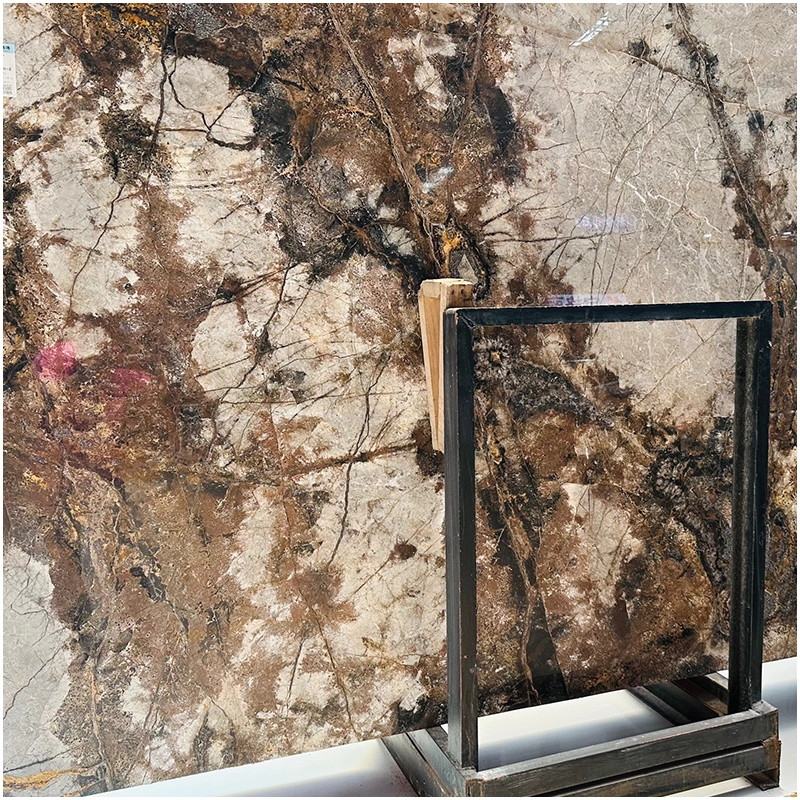

Sorting and filing

Marble is sorted according to color, texture and quality, and then stored in a cool and dry place until it can be further processed.

Marble sorting: To ensure consistency within the same batch of goods, marble is sorted according to color, texture and quality.

To avoid contamination and damage, store sorted marble slabs and blocks in a dry, well-ventilated area.

Marble finishing

Fine cutting

Rough-cut marble slabs are finely trimmed to meet final size and shape specifications.

Cutting equipment: Fine cutting of marble is performed using high-precision cutting equipment such as laser or water jet cutting machines.

Dimension control: Ensure that the cut marble slabs are accurate in size and meet design specifications.

Maintain polishing

Precision-cut marble slabs need to be polished repeatedly to enhance the surface gloss and texture.

Polishing: Use a polishing machine to polish the marble surface multiple times from rough grinding to fine grinding to make it gradually smooth.

To achieve a mirror effect, marble is polished using a polishing machine and polishing liquid.

Edge treatment

The edges of marble are treated according to design specifications to improve its beauty and safety.

To eliminate sharp corners, the edges of marble slabs are chamfered.

Edge decoration: The edges are decorated by carving, brushing, etc. according to design standards.

Finishing of marble surface

Glaze treatment

In order to improve the corrosion resistance, waterproof and stain resistance of marble, the marble surface needs to be glazed.

Spotless surface Make sure the marble surface is dry and clean before glazing.

Apply glaze sealer: Apply evenly on the marble surface with a brush or spray gun and wait for it to dry before applying.

Anti-slip treatment

In applications where anti-slip is required, such as kitchens and bathrooms, the marble surface can be treated with anti-slip treatment.

To increase friction, a fine concave and convex structure is formed on the marble surface using sandblasting technology.

To improve the anti-slip ability of marble, marble can be covered with an anti-slip coating.

Marble Product Quality Inspection and Packaging

Quality Inspection

Marble products must pass strict quality inspections before they can leave the factory to ensure that they meet specifications and customer needs.

Appearance Inspection Check the marble surface for flaws, color changes and gloss as well as color, texture and gloss.

Measurement of Size Use measuring instruments to check the size and shape of the marble to ensure that they are correct.

Physical Property Testing: To ensure that they meet the requirements, test physical properties such as compressive strength, wear resistance and hardness.

Packaging and Shipping

After the marble goods are inspected and qualified, they are packaged and safely shipped to customers.

Materials used for packaging To prevent marble from being damaged during transportation, use highly protective packaging materials such as foam pads, plastic films and wooden boxes.

Identification Marking Attach identification labels to the packaging to indicate the model, characteristics and safety instructions.

Transportation Procedures: To ensure that the marble arrives safely at its destination, choose the appropriate mode of transportation, including trucks, containers or sea transportation.

In brief

Marble is produced via a careful and involved procedure. Every step, from mining to fine processing to surface treatment and quality inspection, calls for exact monitoring and cautious execution. Superior marble goods may be produced by scientific methods and strict quality management requirements and are extensively employed in the building, decorating, furniture, and other sectors.