Marble is a high-end ornamental material prized for its natural texture and distinctive feel. Marble’s brittleness makes it prone to shattering during production, shipment, and installation, however. Marble’s appearance suffers as well as financial losses result from this. Consequently, the main emphasis now is on how to successfully stop marble breaking in different connections. The issue of marble breaking during processing, shipping and installation will be covered in great depth in this article along with suggested related preventative actions to guarantee the usage effect and life of marble.

Marble selection and purchase of materials

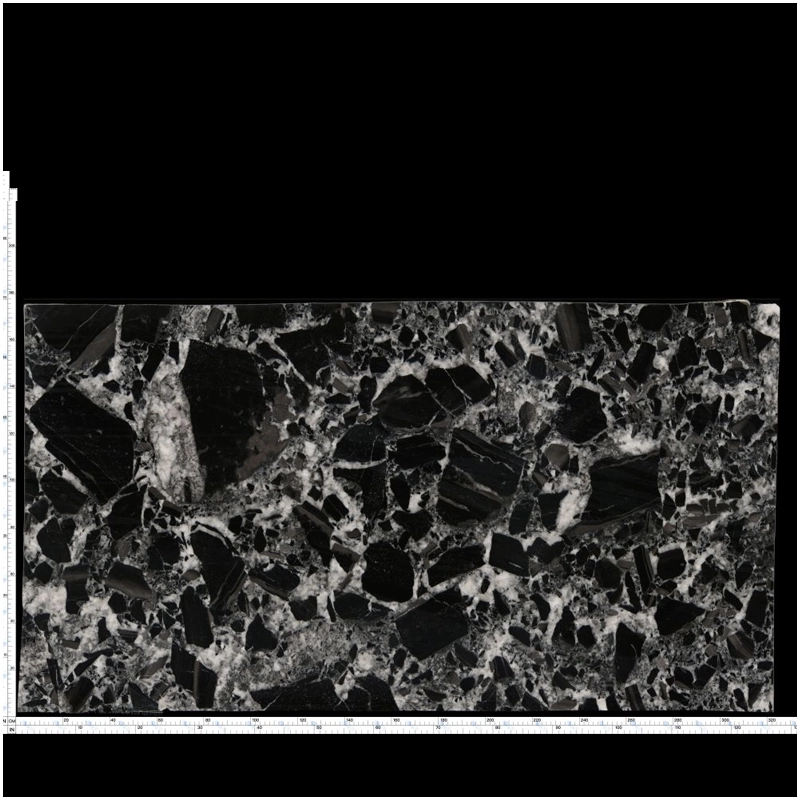

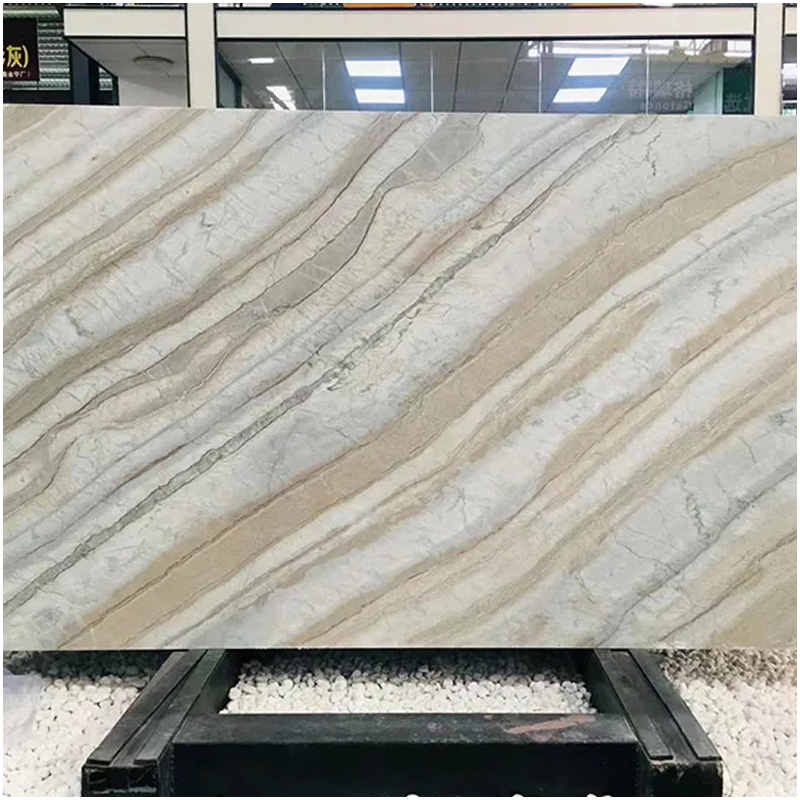

The main connection to avoid fracture in marble is the choice of material. Considerations of the texture, density, and internal flaws of the stone should guide material selection. Generally speaking, marble with homogeneous texture and high density is not simple to shatter and has higher strength. Foru Company gives particular attention to the screening of raw materials when buying marble to guarantee that every piece of stone bought satisfies high criteria. Furthermore avoid buying marble with clear inclusions or fissures, which will raise the breaking risk during further processing and usage.

Safety measures during manufacturing

For manufacturers and workers in construction, the simple breaking of marble during processing usually causes trouble. Usually added to the rear of the natural marble rough board is a back mesh to improve the integrity of the stone and stop it from fracturing. This action may significantly increase the stone’s hardness and lower the breaking risk resulting from outside influences. Foru guarantees that every piece of marble passes rigorous back mesh treatment before leaving the plant and pays particular attention to this aspect when processing it.

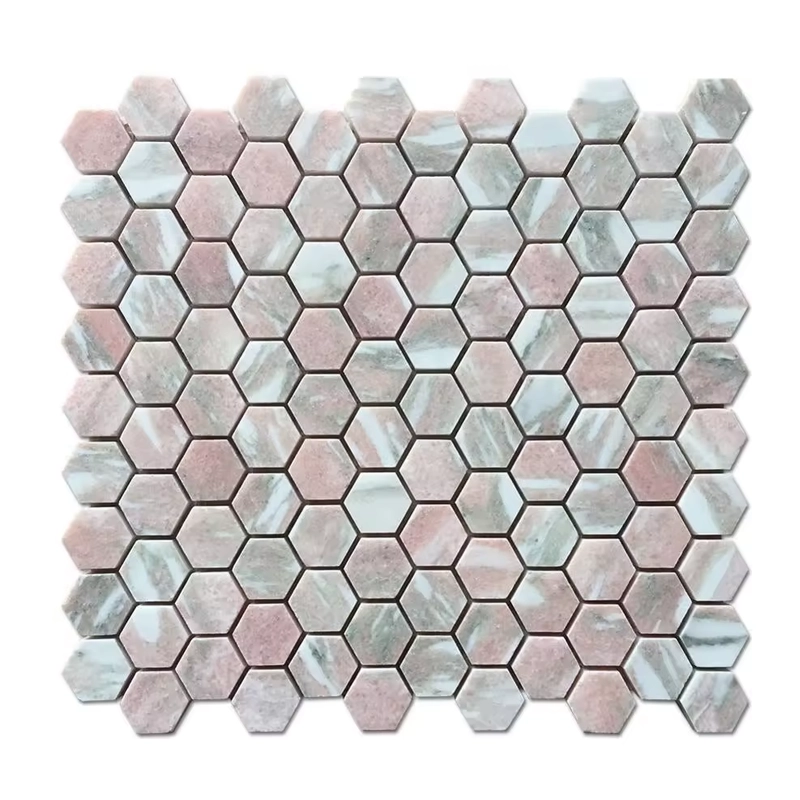

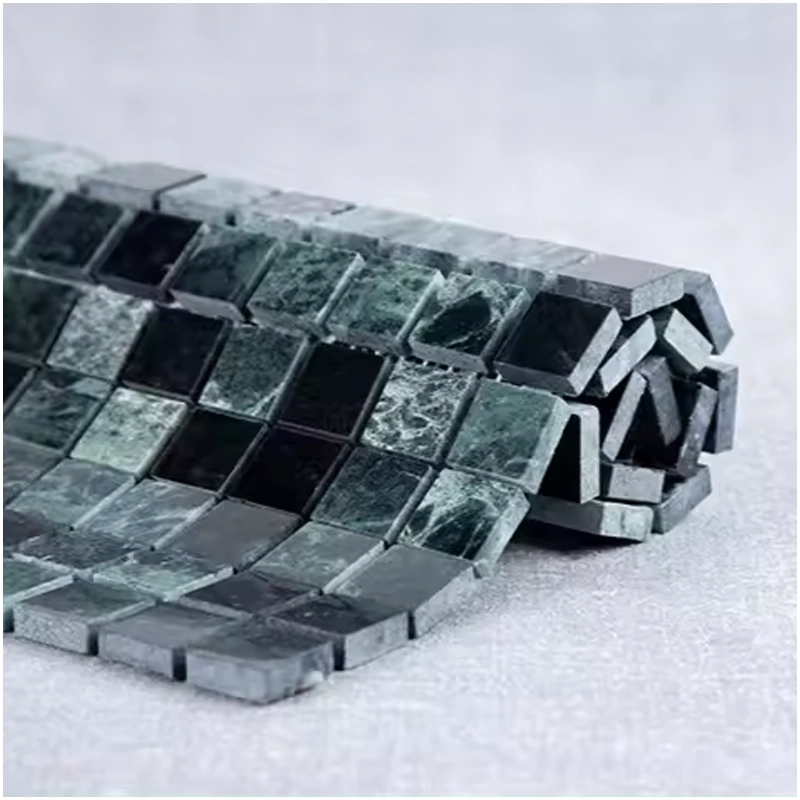

Marble processing also involves size cutting and adjustment. Natural marble’s many shapes and applications mean that the sizes after processing vary too. Breakage is more especially while handling longer or smaller stone slabs. Foru will therefore put reinforcement within the stone slabs with a length of more than one meter while processing marble to improve the structural strength of the stone. Usually, the number of reinforcements is raised for broader slabs to guarantee that they will not break from outside pressures in usage later on.

For cut slabs with less than 10 cm of width, foru often additionally inserts reinforcement on the rear. This is thus because the thin slabs run concentrated stress during production and shipping, increasing their breakability risk. Along with strengthening, certain large-area slabs will have fake stone plastered on their rear to improve their resistance to fracture even more.

Marble management and storage

The right stacking technique is rather crucial during marble storage. Marble should be kept on a level, dry ground to prevent dampness and too high pressure. Strict rules on warehouse management help Foru to guarantee that, with correct atmosphere or stacking, any piece of marble will not create hidden threats during storage. Workers should concentrate especially on the handling methods to prevent local pressure on the marble during the handling procedure. Furthermore lowering the likelihood of marble fracture is the use of suitable instruments for handling, like slings or pallets.

Protective measures during transportation

The marble must be transported to the building site after processing. Vibration and shocks from travel could damage the stone during this procedure. Foru thus covers the smooth surface of the stone with a layer of protective film, which not only helps to prevent fracture but also very successfully avoids surface scratches on the stone. This layer of protective coating gives the stone more defense, much like its “army”.

Furthermore, foru works with seasoned transport professionals to guarantee that every piece of marble is correctly covered during transit. During loading and transportation, experienced masters will follow a set of safety precautions include sandwich shockproof materials between stones to prevent direct stone impact. Concurrent with this will be the drivers of transportation vehicles paying close attention to minimize the effect of road bumps on stones. By use of these exacting precautions, the likelihood of foru’s marble shattering during transit is much lowered.

Safety measures during installation

Another crucial component to reduce fracture in marble is its installation technique. Marble’s general impression and service lifetime depend directly on the quality of installation. carefully adhering to the installation guidelines throughout construction guarantees that every marble piece may be placed securely and level.

Foru advises construction workers laying marble on the ground to first moist the foundation layer then spread a combination of stone powder and cement. This stage not only level the basis but also offers excellent adherence. The stone is then crushed on a layer of cement slurry after which another coating of slurry is deposited on the stone powder layer. To guarantee the stone fits securely to the ground, change the height and push firmly. Walking on the stone considerably lowers the danger of fracture after the cement slurry dries and sets. The stone and ground become a whole then.

For multi-point bonding in wall stone installations, Foru Company advises the use of marble glue and AB structural glue. This approach guarantees not only the stone’s hardness but also helps to prevent stone fracture resulting from wall structural changes. Normally, the stone will not shatter as long as sharp items are not utilized to strike its surface.

Conclusion

Although there is a chance of fracture during the production, shipping, and marble installation, sensible preventative actions may greatly lower this danger. Foru tightly regulates every connection to guarantee the stone’s purity and use impact. From back mesh processing to reinforcement, transportation protection, to professional installation technology, foru aims to do the best in every connection to guarantee that clients may experience high-quality marble decorating effects. Therefore, knowing the specifics and preventative actions in these processing, shipping and installation processes will not only help us utilize marble better, but also prolong its service life and give full play to the beautiful value of marble.