Leading quartz, granite and stone countertop sales, manufacturing and installation company FORU STONE has been Tens of thousands of counters, sinks, and cabinets for every conceivable interior and outdoor project have been placed by us.

Our great experience led us to believe it would be a good idea to compile (and update) our own “Quartz vs. Granite” comparison sheet to assist you in selecting between these two rather different, durable and equally popular materials.

A quartz countertop then is what exactly?

Made man-made, a quartz countertop is a mix of resins and naturally occurring quartz particles. Usually consisting of roughly 90% to 95% natural quartz particles, it also includes resins, colors, and other mineral components. Quartz countertops offer several special benefits over conventional marble or granite ones. First of all, quartz is a really hard material; so, quartz countertops are not readily damaged or worn and are rather hard-wearing and durable. Second, quartz is more hygienic and simpler to clean since its non-porous character makes it less prone to absorb stains or bacteria. For high-frequency use areas like kitchens and bathrooms, quartz surfaces are therefore perfect.

Furthermore, a great range of hues and textures found in quartz counters practically replics the effects of marble or another real stone. Quartz counters can be created in a range of designs to satisfy the needs of various consumers for beauty and personalizing by means of exact craftsmanship. Each countertop’s size, texture, and color can be exactly controlled as it is synthetic, thereby preventing the color difference and unequal texture that would arise from genuine stone.

Apart from their durability and appearance, quartz counters feature decent anti-pollution and antibacterial qualities. The surface of quartz counters is denser and smoother than that of real stone, which helps to efficiently stop oil stains, sewage or other liquids from penetrating. It is safer and more hygienic to use since its surface can not absorb water; so, bacteria or mold cannot flourish on its surface. This function also makes quartz counters especially fit for locations like kitchens and restaurants that call for regular cleaning.

A granite countertop then is what exactly?

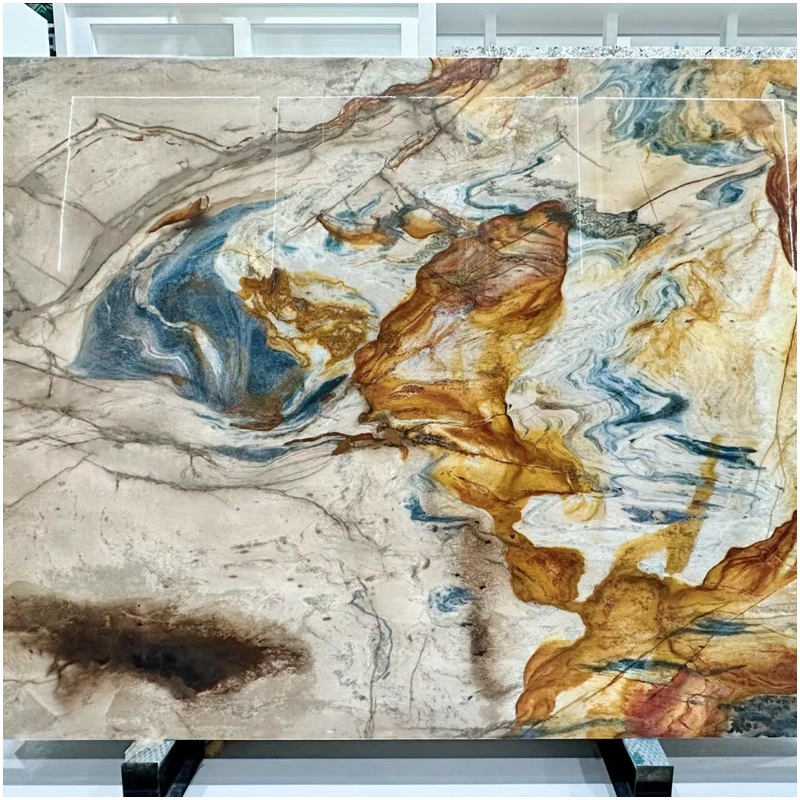

Processed from natural granite stone, a high-end countertop material is granite. With very great hardness and durability, granite is a hard igneous rock made of minerals like quartz, feldspar, and mica. Granite countertops are produced by first cutting, grinding, and polishing natural granite stones to create a level, smooth countertop. Granite is a natural stone, hence every granite countertop has a different color, texture, and pattern that evokes natural and honorable emotions.

Excellent wear resistance, scratch resistance, and heat resistance make granite counters rather sought-after. It is not easy to scratch; its surface is rather robust and can resist different wear and impacts in daily usage. Granite worktops especially fit for high-temperature and high-intensity use areas like kitchens since hot goods like hot pots and kettles are not easily damaged on their surface.

Granite countertops also show high corrosion resistance. Common kitchen cleaners or food wastes cannot readily erode it; it has great resistance to acidic or alkaline compounds. Granite countertops keep their sheen, are easy to clean and maintain, and its surface will not absorb stains in daily usage.

Granite counters have many benefits, but its natural features also mean that every stone has varied texture and color. Thus, depending on their decoration style and personal taste, consumers can select the most appropriate granite style when selecting granite countertops. Furthermore, granite surfaces usually need to be glazed routinely to stop surface water absorption and oil penetration, therefore preserving their beauty and use.

Quartz Products Manufacturing

Usually, the fabrication of quartz counters consists in the following main phases:

Selection and processing of quartz minerals

Usually composed of 90% to 95% genuine quartz mineral powder combined with other components like resins and colors, quartz countertops Manufacturers will first choose premium natural quartz minerals, crush them, screen them, filter them, create quartz particles fit for use. The look and quality of the finished product will directly rely on the texture and color of quartz minerals.

Mixing and batching

High-precision equipment mixes raw components like pigment, resin, and quartz powder. Resins provide adhesives to securely bond the quartz particles together thereby guaranteeing the countertops’ longevity and firmness. Pigments are also employed concurrently to combine textures and colors to satisfy varying design requirements for different consumers. This procedure allows several unique additives to be included to provide the countertops extra qualities including antibacterial, anti-fouling, and anti-ultraviolet capabilities.

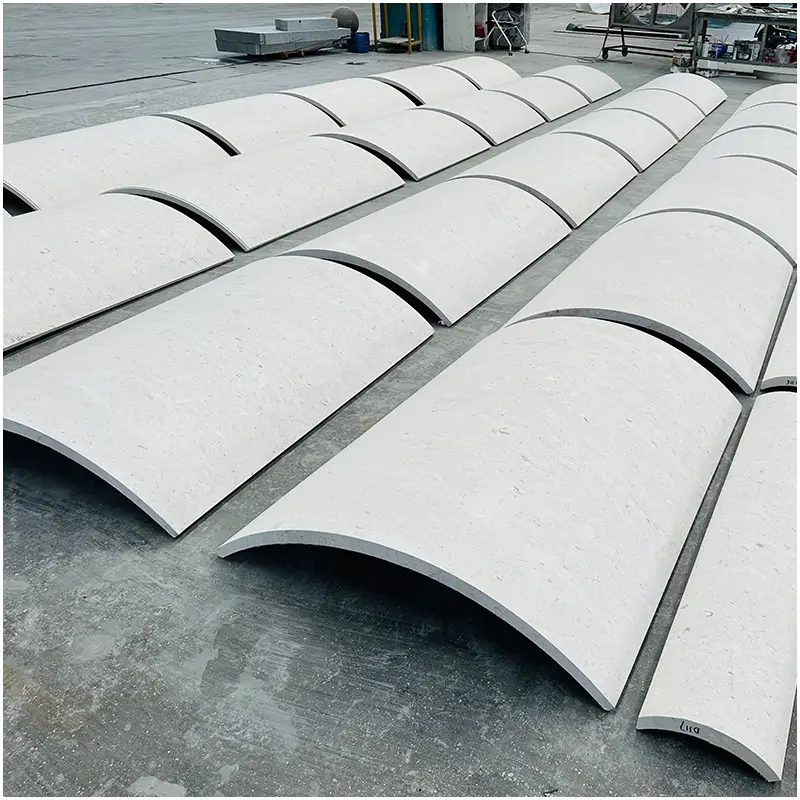

Moulding and pressing

Poured into the mold, the combined quartz material is crushed tightly with pressing technology. This stage guarantees the countertop’s density and homogeneity and prevents bubble and crack development. By better integrating the resin and quartz particles together via high-pressure pressing, the quartz countertop’s durability and strength are increased.

Curing and heating

The quartz countertop created following mold formation will be cured in a high-temperature oven. Resin will react chemically and solidify into a hard substance by heating. This procedure not only increases the heat resistance of the quartz countertop but also raises its wear and scratch resistance.

grinding and polishing

The quartz countertop also requires to be finely polished and polished after curing. Grinding eliminates the uneven surface, so smoothes and flattens the countertop. After polishing, the quartz countertop will show a great sheen, therefore improving its appeal. This stage can improve the visual impression of the countertop surface and make it more sensitive and smooth.

Cutting and processing

The quartz countertop will be handled during manufacture in line with real needs including size cutting and edge trimming. Cutting accuracy is rather crucial as modern quartz counters are typically tailored depending on the real size of the bathroom or kitchen. Apart from simple cutting, secondary operations including drilling and grooving could also be carried out to satisfy sink, stove, etc. installation needs.

Packaging and quality inspection

The quartz countertop will be rigorously tested to guarantee that it satisfies different criteria once all processing operations are finished. Usually, the examination items consist in size, surface flatness, compressive strength, stain resistance, etc. The qualified quartz countertops will be packaged and ready for delivery once the inspection passes.

Quartz Countertop Prices in 2024

Usually driven by rising raw material and transportation costs, quartz countertops’ prices rose in 2024. Low-end quartz counters run between $45 and $70 per square foot (approximately RMB 315–490). For consumers on a tight budget, these counters typically have simple colors and basic textures. About RMB 490–840, mid-range quartz counters run between $70 and $120 per square foot. Most families would find these counters appropriate since they have better quality and more color and texture choices. Usually costing more than $120-$200 per square foot (approximately RMB 840-1400), high-end quartz counters offer special design and customizing options to satisfy the needs of affluent consumers.

Furthermore, as technology develops some quartz counters with marble effects have started to show up on the market in 2024. Usually ranging from $150 to $250 per square foot (approximately RMB 1050-1750), these countertops have more expensive rates.

Granite countertop rates in 2024

Although Granite countertops are usually less expensive than Quartz ones, numerous elements still influence the pricing. Granite counters on low ends run from $50 to $75 per square foot. Usually common black, gray, or white granite, these counters are appropriate for families on a tighter budget. Granite countertops in mid-range cost between $75 and $130 per square foot. Usually having more color and texture choices, these counters are appropriate for customers looking for a distinctive appearance. Usually costing between $130 to 220 per square foot, high-end granite counters Often from uncommon mining sites, they have unique patterns and colors.

The price of some rare and upscale granite kinds keeps rising as the difficulty of natural stone mining grows.

elements influencing prices

The type and grade of the material itself is simply one aspect influencing the cost of granite and quartz counters; other elements also have influence. The pricing will depend first on the brand and provider chosen. Well-known brand counters sometimes cost more than others. Second, the countertop’s thickness and processing will raise the expenses as well. Customized designs (like unique edge forms or holes) or thicker counters will raise the cost. Lastly, especially if the distance of transportation is great or unique installation is needed, the expenses of transportation and installation are very crucial and can rise greatly.

Any countertop’s ultimate installation cost relies on several other elements as well. See our buying and installing countertop guide for further details on these elements.

Color and finish of granite and quartz

Two quite popular countertop materials are granite and quartz. Apart from their physical characteristics, their color and finish—that is, surface gloss—also significantly influence the appearance and utility of the finished good. Granite and quartz color choices as well as popular surface treatments are thoroughly introduced here.

Color and finish of granite

One natural stone with great range of hues and textures is granite. Every bit of granite has a particular pattern and color since it originates from diverse minerals found in the crust of the planet. Typical granite hues consist in:

Black and dark tones: Usually sleek and straightforward, black and dark granite—such as absolute black—and dark gray granite are appropriate for contemporary, minimalist kitchens or bathrooms.

Granite’s light tones—off-white, light gray, beige and cream—give consumers a pleasant and cheerful impression fit for traditional or warm design environments.

Marble effect: Some granites feature marble-like textures, such streamlined patterns in gray and white, which are quite popular and provide bathrooms and kitchens some elegant touch.

Rich colors and patterns abound in some grains, including red, purple, blue, etc.; the way the minerals are distributed creates quite unusual and striking patterns.

Granite surface treatment

Granite surface treatment follows mostly these techniques:

Most often used surface treatment technique for granite is polishing. The surface is glossy and smooth; the color and texture are really strong. Though the surface is more prone to scratches, polished granite is more stain-resistant and easy to clean.

Granite that has been honed feels smoother and more natural, has a softer surface without great sheen. matte counters are excellent for daily use even if they are less shiny than glossy surfaces since they may better conceal stains and fingerprints and resist scratches.

Granite can have a rough texture from flamed surface treatment, which would be appropriate for outdoor use or surroundings needing anti-slip purposes, including walkways or kitchen counters.

Antique: Through a unique technique, the surface is given a retro impression and appears to have little hills and valleys. Many times, it is employed to produce a more classic and retro style house design.

Quartz color and surface treatment

Usually composed of 90% to 95% natural quartz combined with resin and colors, quartz countertops are manmade. Quartz counters provide practically infinite color choices from dark to light, from single tones to intricate patterns thanks to its great customizability. Typical hues range from:

Classic monochrome: black, white, gray, beige, etc., these tones of quartz counters are typically used in modern, minimalist style kitchens and bathrooms.

By use of artificial design, quartz can replicate marble textures, thereby displaying delicate lines and beautiful patterns. Common hues that would be rather appropriate for classic or opulent designs are white, gray, black, gold, etc.

Some quartz counters copy the texture of natural stone, such imitation granite, imitation wood grain, etc., therefore providing consumers with a natural and original experience fit for natural, rustic or industrial style designs.

Rich hues and patterns, such red, blue, green, etc., abound on some quartz counters. These vibrantly colored counters can be utilized as distinctive accents to liven the area.

Surface treatment for quartz

Usually, quartz surface treatments follow these:

Polished: Modern feel, brilliant colors, and a smooth, glossy surface define polished quartz counters. Because polished quartz is easily cleaned and stain-resistant, it is extensively used in high-frequency areas such bathrooms and kitchens.

Matte: For those who appreciate low-key elegance, matte quartz counters lack sheen and have a velvety touch. In daily use, Matte quartz can help to conceal fingerprints and stains.

Sanded quartz counters are suited for outdoor or non-slip settings since their surface is rougher. This surface raises safety as well as beauty.

Some quartz countertops are especially carved to replicate the texture lines of natural stone, therefore giving the countertop more three-dimensional and layered appearance.

Heat resistance: Granite and quartz.

Granite melts entirely at roughly 2400 degrees Fahrenheit—unlikely to happen at house temperature. It also does not promote combustion, and objects placed on its surface will not break or discolor.

Although low-cost models can droop or deform in heat, technically quartz countertops do not melt. Most quartz counters discolor from resin burning if hot objects—typically over 150 degrees Fahrenheit—are placed directly on its surface (such as hot pots, pans, or dishes). Damage this kind cannot be undone.

If the resin temperature is high and the solids to resin ratio is very high, the burning point of mid-to high-priced quartz formulations may be as high as 440 degrees Fahrenheit (be sure to ask whether there is a temperature rating). But if hot objects are placed on their surface, particularly close to sink holes or edges, the lower resin content could lead to significant breaking. Furthermore unable to be rebuilt is this kind of harm.

Our advise is to stay away from directly laying anything hot on your granite or quartz countertop. Burning yourself with hot spots on your granite surface or risking damage to the surface of your quartz countertop is not justified!

Are countertops made of granite and quartz fireproof?

Short answer: Granite countertops are entirely fireproof; man-made quartz counters are not 100%. But just what does that truly mean?

At the evolutionary level of man-made quartz countertops, the lowest grades of this material might support combustion (because of the increased quantity of low-temperature resin binder). Still, most Bretonstone craft supplies no longer support steady combustion.

To be further clear, any grade of man-made quartz will not start a fire since they burn less readily than wood or any other material used in a construction. Furthermore, a lot of other products generate additional harmful gasses in a house or workplace. Quartz products should thus not be regarded as naturally dangerous goods for a household or a business.

Scratch resistance and durability

Granite and quartz counters are among highly durable materials. But two separate things are durability and scratch resistance. Granite would score between 6 and 7 (where 10 is diamond and 5 is metal cutlery) using the Mohs hardness scale, a geological measurement indicating the relative scratch resistance of a material. A higher number indicates stronger scratch resistance).

Quartz countertops score between five and six on hardness. This is so due in great part to a “very soft” polymer resin binder content.

But keep in mind that engineered quartz and granite almost have no difference in scratch resistance as your steel appliances have a hardness rating between 5 and 6. Furthermore, you should not be using your counters as cutting boards anyhow!

Are granite and quartz chip resistant?

There is little likelihood that a manufactured quartz or granite countertop would chip as long as you utilize small overhangs, 3 cm thick slabs, and your manufacturer mills at least a 1/4 inch rounded or “radius” edge (rather than a sharp 90° edge). If chipping does happen, though, most of the time either countertop can be fixed.

Chemical resistance of granite and quartz

Extremely alkaline or acidic cleaning agents (including many solvents, bleach, and dyes) can irreversibly discolor manufactured quartz. For this reason, stain repellents are now advised for quartz counters. They are worth the protection and simple application is easy. Granite is not flawless, but it is almost chemically inert—particularly in cases of pre-treatment with a protective nano-coating.Granite counters let you always polish a surface even if chemicals (or other things) finally dull or blur it. Resealing takes roughly five to ten minutes and is a quite easy process.

Are granite and quartz countertops porous?

Engineered quartz countertops’ polymer resins make them practically non-porous. Given appropriate countertop maintenance, non-porous surfaces are sometimes regarded as a benefit for kitchen and bathroom uses since they reduce the possibility of bacterial growth!

Although some types of granite can be somewhat porous, most granite producers today use a unique nano-coating sealant that will last up to 15 years. Again, though, you have to routinely clean both kinds of counters to keep them hygienic. A non-porous surface by itself cannot guarantee “zero” bacterial growth!

Choose FORU STONE for the perfect quartz and granite countertops

If you are looking for high-quality quartz or granite countertops, FORU STONE is your ideal partner. As a leading quartz, granite and stone countertop sales, manufacturing and installation company, we have extensive experience and have provided exquisite countertops, vanities and cabinets for tens of thousands of indoor and outdoor projects. Whether you prefer the modern style of quartz or the natural charm of granite, FORU STONE can provide tailor-made solutions according to your needs. Not only do our products have excellent durability and beauty, but our professional installation team ensures that every project can achieve perfect results. Welcome to contact us to choose the countertop material that best suits you and give your home a new lease of life.

Choosing Quartz and Granite Countertops

Quartz and granite each have their own unique advantages. Quartz is particularly suitable for high-use kitchens and bathrooms due to its durability, antibacterial and easy-to-clean properties, and its color and texture are more customizable. Granite, on the other hand, is favored for its unique beauty of natural stone, excellent high temperature resistance and scratch resistance, and is suitable for users who pursue personalization and natural beauty. The price difference and maintenance requirements also vary depending on the material type and design. The final choice should be based on personal needs, budget and design style.