Quartz stone slabs have progressively become a star product in the market in contemporary house decorating and construction materials because of their great performance and many application situations. Customers have favored quartz stone slabs from bathroom walls to kitchen counters because of their great look and great durability. Apart from its natural stone’s texture and beauty, current technology’s blessings help it to have additional great purposes. Foru specializes in producing quartz stone slabs and research and development, therefore giving customers premium home decorating materials.

Quartz stone slabs are becoming more and more popular not only because of their great performance but also because they may satisfy contemporary people’s dual desires for utility and beauty. Quartz stone slabs may provide the room a distinctive texture and character regardless of whether it is residential or business. We will next thoroughly examine the benefits of this outstanding material from the fundamental definition of quartz stone slabs, raw material composition, manufacturing technique, market pricing and performance application.

What is quartz stone slab?

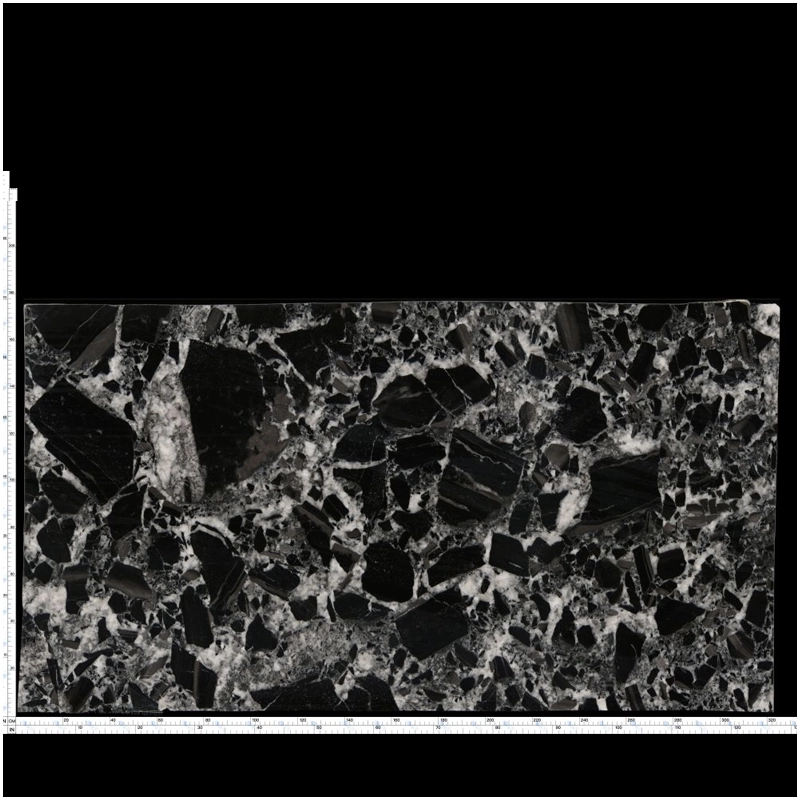

A high-performance composite material with natural quartz as the major component and current technologies produced is quartz stone slab. Usually including more than 90% quartz elements, it is made of resins, colors, and other additions. Widely employed in many spheres of architectural decoration, this high-density material blends the lovely texture of natural stone with the utility of contemporary materials. Although they have great scratch and stain resistance, quartz slabs also provide a wide range of hues and textures, which helps them to seem either exactly like genuine stone or even better.

Quartz slabs have more constant look and quality as their manufacturing process is somewhat under control. While eliminating the color variation and uneven texture that could present in actual stone, it can replicate the feel of natural stones such granite and marble. Apart from their great durability, quartz slabs are quite popular because of their minimal care demands. It simply needs frequent cleaning to keep its beauty and performance; everyday usage calls practically no particular maintenance.

Quartz slabs’ raw components

Quartz sand, a mineral noted for its hardness and chemical durability, is the primary raw component used in quartz slabs. Quartz slabs are produced from fine-grained quartz sand during grinding. This material’s second only hardness is that of diamond, which helps quartz slabs to withstand everyday use’s scratches and wear and preserve long-term attractiveness. Simultaneously, the chemical inertness of quartz sand enables quartz slabs to retain steady performance when confronted with different chemicals in household and business contexts, and will not be readily corroded or discolored.

Apart from the quartz sand, the manufacturing of quartz slabs calls for the binder resin. Along with providing the slabs with some flexibility and hardness, this polymer substance assists them to have a constant structure throughout the molding process. Furthermore included during manufacturing are many colors and other additions meant to improve the slabs’ appearance and use. The ultimate quality and market performance of quartz slabs depend directly on the choices and ratios of these basic ingredients.

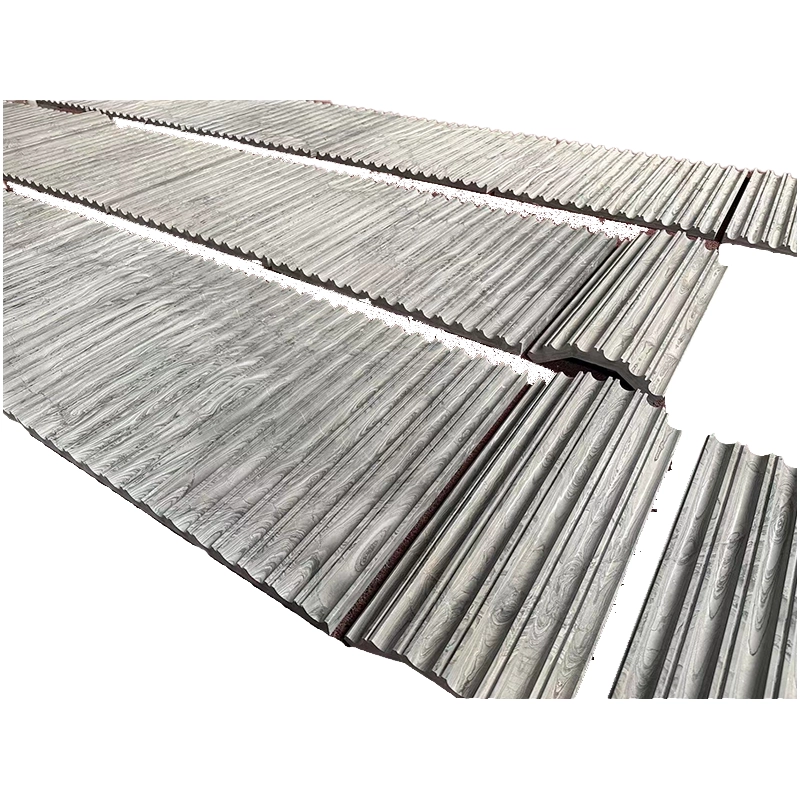

Quartz stone slab manufacture procedure

One might consider the manufacturing of quartz slabs as a procedure that exactly blends technology and environment. To guarantee the homogeneity and density of the mixture, first quartz sand is precisely ratio combined with raw ingredients like resin and pigment under a vacuum atmosphere. In this procedure, the use of a vacuum environment not only removes bubbles in the material, but also enhances the density of the completed result, making the slab more robust. The slurry is then placed into a mould for compression moulding, and high-pressure treatment generates the first slab form.

To improve their structural integrity, the produced slabs also must be treated at high temperature. The resin and the quartz particles develop a stronger link throughout the curing process, therefore enhancing the slab’s hardness and endurance. At last, the slab will reveal the shine of natural stone and undergo many polishing procedures to create its surface level and smooth. Foru guarantees that every quartz stone slab has outstanding performance and attractive look by using modern techniques and tools.

Typical quartz stone slab size and thickness

| Typical Size and Thickness | Description |

|---|---|

| Width | Typically between 760 mm and 1600 mm |

| Length | Typically between 2440 mm and 3050 mm |

| Thickness | Usually ranges from 12 mm to 30 mm; common thicknesses are 20 mm and 30 mm |

| Application | Used for kitchen counters, bathroom counters, walls, and flooring |

| Custom Sizes | Larger or smaller sizes can be customized for specific requirements in some unique applications |

Quartz Stone Slab Price

| Price Range | Description |

|---|---|

| Standard Quartz Stone Slabs | Typically range from ¥500 to ¥3000 per square meter |

| Common Specifications and Colors | Generally priced between ¥800 and ¥1500 per square meter |

| High-End Custom Quartz Stone Slabs | Prices can reach ¥3000 per square meter or more for complex patterns or imported high-quality materials |

| Provider | Foru offers quartz stone slabs in various price ranges to meet different consumer needs |

| Buying Considerations | Consumers should choose based on their needs and budget, considering both aesthetics and cost-effectiveness |

Applications and Performance

Excellent performance of quartz stone slabs has made them a perfect option for both domestic and business décor. First of all, quartz stone slabs can keep long-lasting sheen and beauty in high-frequency usage locations like kitchen countertops and have very great hardness and wear resistance. Quartz stone slabs can readily handle everything, even the impact of a heavy item or the scratch of a knife, therefore guaranteeing the integrity of the countertop. Besides, its anti-fouling quality is really excellent. The quartz stone slab’s surface is solid and non-porous, hence stains are harder to get through and everyday cleaning is simpler.

Quartz stone slabs have applicability outside of kitchen and bathroom counters. It is also quite common in many ornamental areas like walls, floors, and staircases. Its vast color and texture range helps it to fit rather well into many home design trends. Quartz stone slabs may provide a lot of color to everything, from opulent environment to contemporary minimalism. Simultaneously, quartz stone slabs’ strong temperature resistance and corrosion resistance have made them extensively employed in specialized settings such hospitals and laboratories. Customers have praised Foru’s quartz slabs especially for their great performance.

With their special qualities, quartz stone slabs have progressively taken the stage among contemporary ornamental materials. By means of the aforementioned in-depth analysis, we can see that quartz slabs not only have notable performance benefits but also can satisfy the expectations of various customers about beauty and pricing. Foru is dedicated on offering customers premium quartz slabs to satisfy various demands for business and household design. Quartz slabs are definitely a very good investment decision for those who value quality and beauty. Quartz slabs may provide your area a distinctive beauty and utility whether used in home décor or in the design of business space.